GET A QUOTE

Bila Solutions

Global AGV L14 | Stand-alone logistic solution

All pallet flows can be monitored from all devices, so your customers can follow and optimize everything from workflows to flow analyses and make savings of up to 60% on simple pallet transport jobs.

Pallet handling

The Global AGV L14 is a stand-alone logistic solution that autonomously registers where and when the pallets need to be picked up and delivered and synchronizes with other logistics processes.

With its 360° navigation system at a height of 2.2 metres, the Global AGV constantly scans its surroundigs to safely transport goods alongside people and other equipment.

If an employee or another obstacle obstructs the AGVs route or safety zones, the AGV stops and keeps a safe distance. Once the object is removed, the AGV automatically continues its route.

AGV Beneleux provides:

- Improved efficiency by working 24/7-365

- Less collision damage to goods and equipment

- Simple integration in existing environments

- Straightforward installation in just 2 to 3 days

- Flexible and easy route configuration

- Dual mode with manual operation

- Intuitive interface – the same on computer, tablet or phone

- Short payback time in less than 1 year.

Specifications

The Global AGV L14 is suitable for handling VS, UK en SEA pallets

Capacity 1400 kg / 3086 lb

Lift height max. 2844 mm. (112") Limit: 1000 mm (39.4")

Fork dimensions 60 x 180 x 11500 mm (1.6" x 3.9" x 47.2")

Between forks Fixed at 380 mm (15")

Engine 1.5 kW AC Engine

Transmission Linde AC transmission

Max. speed 1.2 m/s

Pallet types

The Global AGV L14 can handle the following pallet types

EUR-pallets 1200 x 800 x 144 mm (47,2" x 31,5" x 5,7")

Industrial pallets 1200 x 1000 x 150 mm (47,2" x 39,4" x 5,9")

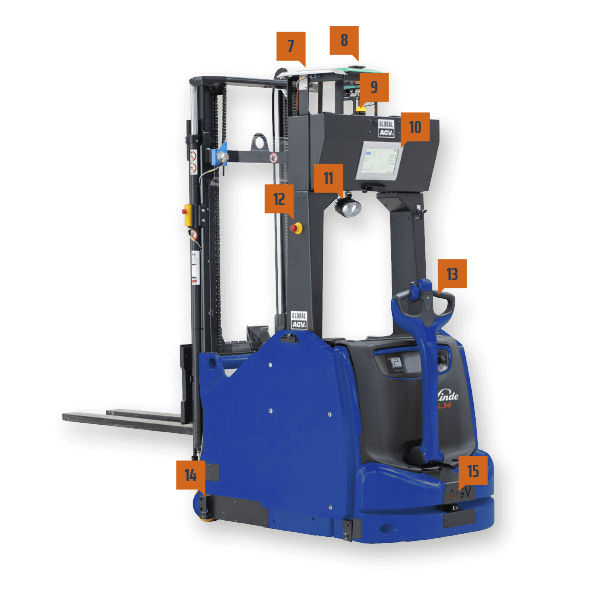

Global AGV L14 standard equipment and options

- Red spot (warning light) - signals to the surroundings that the AGV is reversing

- Warning signal (side) - indicators that show which way the AGV is turning and signal when it is in the docking station

- Load sensor - located on the lifting tower to detect if the pallet or cargo is positioned correctly

- Safety scanner (rear facing) - MODEL SICK S300 Expert detects objects located in the AGVs direction of travel

- Marshalling detection scanner - located on the back of the AGV, allowing for safe and efficient collection and delivery in lanes

- Fork sensors - located at the end of the forks to detect if something is located in front of the AGV

7. Automatisk charging top - allowing the AGV to be charged during breaks

8. Top scanner - Pepperl+Fucks (2D LiDAR) navigation laser scanner with 360° view

9. Warning signals (light and sound) - located on both sides and top of the AGV. The signal is used to indicate turning and connecting to the docking station.

10. Touch screen - intuitive interface that gives the operator control and system information

11. Blue spot (warning light) - signals to the surroundings that the AGV is moving forwards

12. Emergency stop

13. Handle for manual operation - allows for manual operation when switching routes or mapping the AGV

14. Safety sensor (side) - located at the bottom right and left hand sides to detect objects such as feet

15. Safety scanner (front) - Model SICK S300 Expert detects objects located in the AGVs direction of travel

Installation

Installed within 2 - 3 days

Reliable partner

More than 25 years of experience

Service

Service support 24 / 7

Our logistic experts

Our expert service and maintenance team consider it their most important task to make your everyday life easier

With vast know-how and more than 25 years of experiece, we at AGV Benelux offer you not only the very best quality, but also a wide range of AGVs.

We know the market better than anyone and are specialist in packing machines, tilting pallet lifters and streamlined logistics.